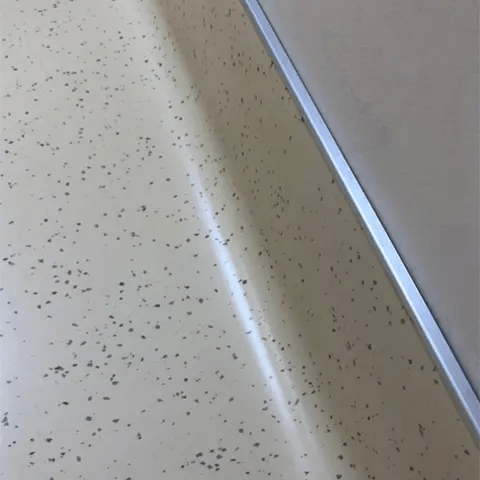

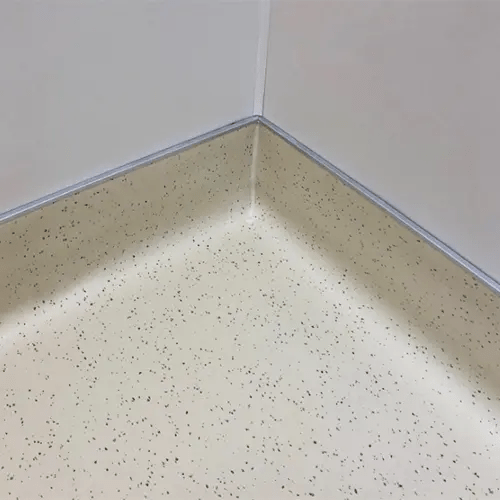

Flash coving allows flooring to promote sanitary conditions, ease of maintenance and protection against accumulation of dirt, water and moisture that gather at the base of vertical structures. This area is hard to clean correctly and bacteria can accumulate and grow, which is particularly dangerous in operating rooms where all efforts must be made to avoid contamination. Moreover, as our products contain no volatile plasticizers, they will maintain their resilience and will not crack when curved.